The Superior Works: Patrick's Blood and Gore Planes #39 - #44

Quick Find: #39, #40, #40 1/2, #41, #42, #43, #44

Now that the "boring" bench planes have been

enumerated (there's

more, but they're later in the numbering sequence), it's

time to look at some

of the more interesting specialty planes.

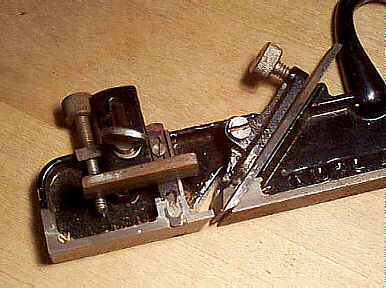

#39 Dado plane, 8"L, various widths (see below), 1 3/4lbs-2 1/4lbs, 1902-1952.

These planes, 8 all together, are designed to cut a dado, a trench across the wood's grain, and are the metallic versions of the earlier wooden ones. Like the wooden dado planes, a wooden batten must be laid aside the dado's position to guide the plane. An adjustable depth stop regulates how deep into the wood's surface the plane will cut. These planes can be used left or right handed, just like the wooden ones, an example of which is illustrated immediately below.

All the planes have their blades set at a skew, with

two adjustable spurs

forward of the blade to score the wood (across the dado's

width) before the

blade makes its cut. The skewed iron facilitates cutting

across the grain by yielding

more of a slicing cut than there otherwise is were the blade

not skewed; the

compression of one fiber against another is minimized with a

skewed iron where

the compression is spread out over several fibers in the

path of the iron

whereas with a non-skewed iron the compression is placed on

a single fiber in

the path of the iron. But, more on the dado cutting action

later.

I don't like these

planes

at all, not because they're metallic planes, but because

they are difficult to

put any bearing pressure on their toes. There simply isn't a

nice surface for

your forward hand. Instead, the metal depth adjustment

screw, as well as the

tops of the spurs, stick up from the top of the plane, which

physically hurts

your hand as the plane is used. This isn't that much of a

hindrance when the

planes are used on softer woods, but they're downright

bloody when using them

on hardwoods. They also have the disadvantage of being more

expensive than the

wooden ones, but their soles don't warp like the wooden ones

can. Regardless

whether you prefer the metal or wooden dado planes, they

both cut fabulous

dados, and amaze dado'ers of the 'lectrical persuasion with

their simplicity

and results. The swell thing about dado planes in general is

that you can taunt

normites by asking them how they would cut a dado 45 degrees

from the edge of

the stock using their beloved stack dado cutter, and then

watch them go through

the dog and pony show of rigging up some fancy jig to try

and pull it off. With

these planes, you can bury them in the shavings that'll pile

up by the time

they make their first cut.

I don't like these

planes

at all, not because they're metallic planes, but because

they are difficult to

put any bearing pressure on their toes. There simply isn't a

nice surface for

your forward hand. Instead, the metal depth adjustment

screw, as well as the

tops of the spurs, stick up from the top of the plane, which

physically hurts

your hand as the plane is used. This isn't that much of a

hindrance when the

planes are used on softer woods, but they're downright

bloody when using them

on hardwoods. They also have the disadvantage of being more

expensive than the

wooden ones, but their soles don't warp like the wooden ones

can. Regardless

whether you prefer the metal or wooden dado planes, they

both cut fabulous

dados, and amaze dado'ers of the 'lectrical persuasion with

their simplicity

and results. The swell thing about dado planes in general is

that you can taunt

normites by asking them how they would cut a dado 45 degrees

from the edge of

the stock using their beloved stack dado cutter, and then

watch them go through

the dog and pony show of rigging up some fancy jig to try

and pull it off. With

these planes, you can bury them in the shavings that'll pile

up by the time

they make their first cut.

The planes came in the following widths (not all

planes were available during

each year of production) - 1/4", 3/8", 1/2", 5/8",

3/4", 13/16", 7/8", and 1". The earliest models don't have

their number and size embossed on their left side, but,

instead, have them both

cast into separate ovals on the right side, which is

machined flat, with the

backgrounds around the number and size being japanned. On

these models, the

number (cast as "NUMBER 39" forward of the handle) and size

(cast

near the toe) are embossed in separate shallow depressions,

which probably

proved difficult to cast with any regularity. The number and

size were soon

relocated to the left of the plane. The patent date is cast

into the handle on

the first and subsequent models, but was later replaced with

just

"STANLEY" cast into the handle starting around the

sweetheart era

(ca. 1920).

All of the planes have

their size cast on them, except for one, the 13/16" model.

This is because

this plane was made from a 7/8" size, which was then ground

narrower to

13/16". The 7/8" marking was ground off the plane before it

was

japanned, but the "No. 39" remained on the casting. This is

one of

the rarest Stanley planes (think about it, how many

applications do you know

where a 13/16" dado is used?). Because of its rarity, some

clever latter

day toolmakers have attempted their hand at making the

product, so be very

careful of those that have been re-ground recently. There

should be a circular

mark where the 7/8" mark was ground off, if it is an

original 13/16".

However, the good faker can make this mark, too. Check the

japanning in the

area of the removed mark to verify its authenticity. Caveat

emptor on this one!

All of the planes have

their size cast on them, except for one, the 13/16" model.

This is because

this plane was made from a 7/8" size, which was then ground

narrower to

13/16". The 7/8" marking was ground off the plane before it

was

japanned, but the "No. 39" remained on the casting. This is

one of

the rarest Stanley planes (think about it, how many

applications do you know

where a 13/16" dado is used?). Because of its rarity, some

clever latter

day toolmakers have attempted their hand at making the

product, so be very

careful of those that have been re-ground recently. There

should be a circular

mark where the 7/8" mark was ground off, if it is an

original 13/16".

However, the good faker can make this mark, too. Check the

japanning in the

area of the removed mark to verify its authenticity. Caveat

emptor on this one!

These planes, while overall ruggedly built, can often

be found with broken

parts. Of those that are damaged, it's usually a broken or

missing spur or the

lever cap snapped off below its pivot point. The lower edge

of the lever cap

can chip, but how that happens is beyond me, unless the dude

was planing

granite or something like that. Check that the depth stop

isn't broken down

where the stop's adjusting screw threads into it - they can

break out around

there. These are obvious problems that stick out like a sore

thumb.

The planes are often

found missing their cutters. Finding replacements for them

is tough since the

cutters are unique to the series. They have bevelled edges

and flare out on

their right edges. The spurs are held to each side of the

plane with two screws

each; one screw, the lower one, is countersunk so that it

sits flush with the

spur, while the upper larger screw sits above the spur.

Missing spur screws is

a common problem with these planes. Most of the spurs are

unique to the size of

plane for which they were designed, so salvaging them can be

a problem.

However, the rightmost spur, since it's flat, unlike the

leftmost ones that are

bent to each size plane, can be pilfered from other planes

as all the planes of

the series are machined flat on their right

sides. The most common

damage to the spurs, other than their being used up, is a

crack about the lower

screw, near the business end of the spur. One other thing to

be watchful for,

as any dealer or collector of these planes knows all too

well, is that the

spurs are not interchangable between the earlier and later

types; the earlier

ones are narrower than the later ones, and the slots that

they fit into are

sized accordingly.

The planes are often

found missing their cutters. Finding replacements for them

is tough since the

cutters are unique to the series. They have bevelled edges

and flare out on

their right edges. The spurs are held to each side of the

plane with two screws

each; one screw, the lower one, is countersunk so that it

sits flush with the

spur, while the upper larger screw sits above the spur.

Missing spur screws is

a common problem with these planes. Most of the spurs are

unique to the size of

plane for which they were designed, so salvaging them can be

a problem.

However, the rightmost spur, since it's flat, unlike the

leftmost ones that are

bent to each size plane, can be pilfered from other planes

as all the planes of

the series are machined flat on their right

sides. The most common

damage to the spurs, other than their being used up, is a

crack about the lower

screw, near the business end of the spur. One other thing to

be watchful for,

as any dealer or collector of these planes knows all too

well, is that the

spurs are not interchangable between the earlier and later

types; the earlier

ones are narrower than the later ones, and the slots that

they fit into are

sized accordingly.

If handcut dados are in your future, you may want to

consider getting the #46 since its

purchase price is considerably less than buying the series

of the #39s.

Plus, the #46 is more versatile as it can

plough, rabbet, and

match. However, if you know you're only going to work 3/4"

stock, for

example, then buying the #39 3/4

is more economical than buying a complete #46.

For any dado plane, wooden or metallic, to work

correctly, the nickers need

to be set just a hair deeper than the cutter. The nickers

need to score the

wood fibers prior to the cutter lifting the shaving. The

edges of the cutter

must be aligned with the line scored by the nickers

otherwise ratty shoulders

result. If the plane binds during use, a misalignment

between the nickers and

cutter may be the reason. It also may be from an improperly

ground cutter,

where the edges themselves flare out just a hair causing

them to drag along the

shoulders. These edges do not need to be beveled back so

that the width of the

bevel face of the cutter is narrower than the face's. This

is a common

misconception, and the plane will work fine if the widths of

both faces are the

same. When the cutter and spurs are set just right, you can

peel off crossgrain

shavings of a length equal to the length of the dado and

leave the adoring

public speechless over a feat thought impossible by the

paint by number

woodworkers out there.

And for those who are into the great mysteries of

life, like what's the

opposite of bread, one can contemplate forever over how

Stanley got the depth

stops on these planes. It's sorta like Stanley's version of

the Rubic's Cube.

#40 Scrub plane, 9 1/2"L, 1 1/4"W, 2 1/8lbs, 1896-1962.

This is Stanley's version of a scrub plane, designed to remove a lot of wood quickly. It has a very thick blade (without a cap iron) which is ground convex, and a very wide mouth, all of which make the act of removing large amounts of stock, sometimes called "hogging", happen easily.

The plane

has a

knob and a tote, both made of beech. The tote looks like the

common beech tote

used on the transitional planes, but the knob is shaped

differently - it's much

taller, and resembles the rosewood hi-knob version used on

the metallic bench

planes. The earliest knob is rather shapely, and has a fast

taper to its

diameter where it meets the casting.

The plane

has a

knob and a tote, both made of beech. The tote looks like the

common beech tote

used on the transitional planes, but the knob is shaped

differently - it's much

taller, and resembles the rosewood hi-knob version used on

the metallic bench

planes. The earliest knob is rather shapely, and has a fast

taper to its

diameter where it meets the casting.

There are some examples of this tool with rosewood

knobs and totes, but they

are later models and seem to be scarcer than those equipped

with beech. The

switch from beech to rosewood may have had something to do

with Stanley finally

dropping the beech transitional planes during WWII; they no

longer needed to

buy beech, and were content just destroying the rainforests.

The finish on the

rosewood is very thick, and it often obliterates the wood's

grain. The WWII

years used the common dark-finished hardwood knob and tote

that was used on the

bench planes.

There are two basic castings used for these planes.

The earlier of the two

has a narrow cross-rib cast between the two arched sides of

the tool. It's on

this cross-rib that the iron seats, lending support when the

lever cap is

tightened. Because of the plane's design, the lever cap

screw sits above the cross-rib,

and can make the iron flex a bit when clamped in place.

Stanley redesigned the

iron's seat, making it T-shaped so that the lever cap screw

sits directly over

the casting, which acts as a buttress.

Check that the lever cap screw can tighten the blade

- sometimes the screw

can bottom out before applying enough pressure on the blade.

Also check that

the lever cap itself hasn't been snapped in two, and then

repaired.

The plane's main casting is entirely japanned, except

for the sole. Scrub

planing wood can be hard work, which often generates

rivulets of sweat dripping

down your forearms onto the plane. Sweat and bare metal

don't make a happy

couple, so Stanley may have japanned their exteriors to keep

the plane spiffy

looking as long as possible. Most examples of the plane,

however, exhibit a

ghastly appearance from years of toil.

These planes are hard to ruin physically since

they're quite ruggedly built

to handle the job for which they are designed. If you're at

all into preparing

rough stock, this is one plane to own. Even the most

die-hard power tool junkie

can successfully use this plane, but be careful if you fall

into that gene pool

- it might just be your baptism into the spiritual world of

handtool

fundamentalism.

#40 1/2 Scrub plane, 10 1/2"L, 1 1/2"W, 2 1/2lbs, 1902-1948.

Same as the #40, only a bit larger, and much less encountered. Check that the lever cap's width is equal to the iron's to ensure that it isn't a replacement from the narrower #40.

#41 Miller's Patent Adjustable Metallic Plow, Filletster, Rabbet, and Matching Plane, 9 7/8"L, various widths, 4lbs, 1871-1895. *

This is the

first in a series of combination planes that Stanley

introduced in an attempt

to counter the wooden plane equivalent that had become the

standard for this

type of work. Its primary function is as a plough plane.

This plane is

beatifully cast with floral scrollwork on its body, fences,

and fillister

bottom and is a fine example of Victorian extravagance that

permeated design

and form no matter the object. This was a calculated act on

Stanley's part, due

to the competition with the wooden ploughs that were often

the showpiece of the

master cabinetmaker - wooden ploughs at this time were often

made of an exotic

wood, most often boxwood and/or rosewood, and were sometimes

decorated with

ivory trimmings. Had Stanley introduced this plane as just a

chunk of metal,

which they easily could have, it likely would have suffered

a different fate -

surely no workman was going to turn in his fancy wooden

plough for some

unsightly chunk of metal. Many of them did bite on the bait,

transforming wood

into metal, and Stanley sold a considerable number of these

planes.

This is the

first in a series of combination planes that Stanley

introduced in an attempt

to counter the wooden plane equivalent that had become the

standard for this

type of work. Its primary function is as a plough plane.

This plane is

beatifully cast with floral scrollwork on its body, fences,

and fillister

bottom and is a fine example of Victorian extravagance that

permeated design

and form no matter the object. This was a calculated act on

Stanley's part, due

to the competition with the wooden ploughs that were often

the showpiece of the

master cabinetmaker - wooden ploughs at this time were often

made of an exotic

wood, most often boxwood and/or rosewood, and were sometimes

decorated with

ivory trimmings. Had Stanley introduced this plane as just a

chunk of metal,

which they easily could have, it likely would have suffered

a different fate -

surely no workman was going to turn in his fancy wooden

plough for some

unsightly chunk of metal. Many of them did bite on the bait,

transforming wood

into metal, and Stanley sold a considerable number of these

planes.

The plane has a nicely finished rosewood tote, which

is stamped with

Miller's patent date on its left side. The tips/horns of

these totes are often

broken since they extend back a great deal with little to

support them other

than the wood's grain (later models of the plane overcame

this defect simply by

making the tote with smaller horns). The totes are fastened

to the cast frame

with pins. The earliest models use two pins to fasten the

tote to the frame,

whereas the later ones use only a single pin. Frequently,

the totes are cracked

in two around the pins or have tote chunks missing about the

pins.

The

earliest

models, often called "humpbacks", have a pronounced hump

starting

just behind the screw that activates the brass lever cap

(doubles as a chip

deflector) to secure the iron in place. The hump terminates

with a graceful,

looping, and hook-like return at the top of the tote. The

later models have

more of an S-shape from the screw to the tote. There are

also other ways to

date these planes, such as the type of screws used on them

(brass surrounding a

slotted round-headed screw vs. all brass screw vs. slotted

brass screw), the

fence style (two fences vs. one fence with two sets of

holes), the chip

deflector (stubby and angular vs. larger and curvilinear),

the endpoints of the

arms (turned acorn-like finials vs. simple rounding), and

the slitting cutter

(absent or present). Whatever the vintage of the plane, they

all have the

elaborate castings, but the earliest ones fetch the most

moolah from

collectors.

The

earliest

models, often called "humpbacks", have a pronounced hump

starting

just behind the screw that activates the brass lever cap

(doubles as a chip

deflector) to secure the iron in place. The hump terminates

with a graceful,

looping, and hook-like return at the top of the tote. The

later models have

more of an S-shape from the screw to the tote. There are

also other ways to

date these planes, such as the type of screws used on them

(brass surrounding a

slotted round-headed screw vs. all brass screw vs. slotted

brass screw), the

fence style (two fences vs. one fence with two sets of

holes), the chip

deflector (stubby and angular vs. larger and curvilinear),

the endpoints of the

arms (turned acorn-like finials vs. simple rounding), and

the slitting cutter

(absent or present). Whatever the vintage of the plane, they

all have the

elaborate castings, but the earliest ones fetch the most

moolah from

collectors.

The plane came with the following irons - 8 plough

irons, 1/8",

3/16", 1/4", 5/16", 3/8", 7/16", 1/2", and

5/8", a 1/4" tonguing iron, and a 1 5/8" fillister iron. The

irons are very thick with a v-groove on their backsides into

which the skate

fits to grip and align them. These irons are very much like

the typical wooden

plough irons, but not nearly as long.

Starting in 1884, a

slitting cutter was added, which was used to slice thin

sections of wood, a

task commonly done skillfully by using a handsaw. This

slitting cutter has a

separate pressed steel depth stop that fits over it. The two

of them fit over

the rear arm, on the right side of the plane. A large brass

nut, exactly like

the one used for the depth stop, holds them in place by

screwing onto the

threads of the arm. The slitting cutter is held in place

laterally by a

machined recess in the plane's main casting. The slitting

cutter and/or its

depth stop are often missing from these planes. For a very

brief time, a second

brass depth stop, like that used on all models of the

series, was supplied as

the depth stop for the slitting cutter.

Starting in 1884, a

slitting cutter was added, which was used to slice thin

sections of wood, a

task commonly done skillfully by using a handsaw. This

slitting cutter has a

separate pressed steel depth stop that fits over it. The two

of them fit over

the rear arm, on the right side of the plane. A large brass

nut, exactly like

the one used for the depth stop, holds them in place by

screwing onto the

threads of the arm. The slitting cutter is held in place

laterally by a

machined recess in the plane's main casting. The slitting

cutter and/or its

depth stop are often missing from these planes. For a very

brief time, a second

brass depth stop, like that used on all models of the

series, was supplied as

the depth stop for the slitting cutter.

Stanley, in its advertising literature about the

planes, gave unique names

to the fences that came with the planes. They called the

ornately cast

fillister fence the "gate", and the shorter fence the

"gauge", which was an optional feature for this and the #42 planes. In deference

to modern vocabulary, fillister fence and ploughing fence

are used in the

descriptions that follow.

Since there are many subtle changes to the castings

during the plane's

production, one has to be careful about buying one for parts

to complete one

that is missing some. One of the more common problems with

this plane is its

delicately cast fillister fence, which can easily break if

the plane is

mistreated. This fence rides on two arms that are screwed

into the plane's

body. Usually, the distance the arms are apart from each

other varies ever so

slightly, which can make for a tough time to find a suitable

fence replacement;

the fence will fit onto the arms, but it can bind as it is

slid closer to the

body due to the misalignment of the fences holes and the

position in the main

casting where the arms are tapped.

The chip deflector, which doubles as the bearing part

to secure the iron, is

made of brass and can break or bend along its length. It is

secured to the

plane with two screws. Many examples are missing a screw or

have replacements.

The earliest models used round-headed screws to attach the

chip deflector, with

the later ones using flat-headed screws. The depth gauge is

made of brass, and

it can sometimes get banged up making it difficult to slide

along its entire

length. The depth gauge slips over the the right portion of

the forward arm,

and a brass knurled nut, like that used with the slitting

cutter, is screwed onto

the arm to lock the gauge in position. A brass washer is

proper to the depth

stop and nut.

The

fillister

bottom screws to the skate of the plane - there are two

slots in the skate, one

before the cutter and one behind the cutter, with each slot

accepting its

corresponding screw. Check that the screws aren't

replacements. They should

have flat heads, and fit snuggly into the slots provided

them. The fillister

beds are not interchangeable between the earlier and the

later models; the

position of the screws is just slightly different to allow

proper alignment of

the bed to the plane. The fillister bottom carries the wide

fillister iron,

which is set at a skew to the fillister bottom. A large

slotted screw and a

brass washer hold it in place. A spur is provided on the

bottom, forward of the

cutter, to score the wood's grain before the iron cuts it.

This spur is

dovetailed in place, and often is frozen in place. Many

planes are missing the

fillister bottom altogether. If it is, and you're seeking a

replacement, the

line forms at the rear.

The

fillister

bottom screws to the skate of the plane - there are two

slots in the skate, one

before the cutter and one behind the cutter, with each slot

accepting its

corresponding screw. Check that the screws aren't

replacements. They should

have flat heads, and fit snuggly into the slots provided

them. The fillister

beds are not interchangeable between the earlier and the

later models; the

position of the screws is just slightly different to allow

proper alignment of

the bed to the plane. The fillister bottom carries the wide

fillister iron,

which is set at a skew to the fillister bottom. A large

slotted screw and a

brass washer hold it in place. A spur is provided on the

bottom, forward of the

cutter, to score the wood's grain before the iron cuts it.

This spur is

dovetailed in place, and often is frozen in place. Many

planes are missing the

fillister bottom altogether. If it is, and you're seeking a

replacement, the

line forms at the rear.

The background of the castings is japanned, and the

high points are machined

flat, which combine to give the plane a striking appearance.

There is no number

cast into the plane, but the skate, which is fashioned from

steel and is pinned

to the main casting, usually has the imprint of Stanley Rule

and Level Co.

stamped into the right rear of it. While looking for the

company's logo, check

that the casting, where it meets the rosewood handle, above

and below, isn't

cracked or repaired.

Enough examples of the plane can be found equipped

with the two fences,

which offers ample proof that many woodworkers of the day

had some money

burning a hole in their pockets in order to incur the

additional expense of the

optional ploughing fence. The fillister fence is used along

with the fillister

bottom, but can be used without the fillister bottom during

normal ploughing

operations. The fillister fence has two looping areas that

extend beyond the

positions of the two arms so that it can fit over the

fillister bottom and

regulate the width of cut. The fence's length is a bit

longer than the plane's

skate. This is the fence that can be damamged easily. The

other fence is

shorter, a bit shorter than the plane's skate, and is used

for general

ploughing. Both fences have floral patterns cast into them,

but the fillister

fence is more ornate.

During the mid-1880's, the two fence version was

dropped for a model that

carried only one. The plane itself remained relatively

unchanged (other than

the addition of the slitting cutter), with the fence

undergoing a redesign. The

new fence has 2 sets of holes to receive the plane's arms,

with one set

directly over the other. The fence curves toward the plane's

skate, so the

top-most set of holes is used with the fillister bottom, and

the bottom-most

for normal ploughing. This fence is always iron (an

important distinction for

the plane that follows).

#42 Miller's Patent Adjustable Metallic Plow, Filletster, Rabbet, and Matching Plane, 1871-1892. *

This plane is

identical to the #41,

except that it is made from gun metal, an alloy of copper

(88% copper, 10% tin,

and 2% nickel), similar in appearance to bronze. Since

this plane isn't made of

iron, like the #41, it is somewhat malleable. Dropping it on a hard

floor won't

necessarily break it, like an iron one is apt to suffer.

Instead, the metal

will bend a bit before it breaks, so check for ones that

have been mistreated

by sighting down its skate - it should be perfectly

straight.

This plane is

identical to the #41,

except that it is made from gun metal, an alloy of copper

(88% copper, 10% tin,

and 2% nickel), similar in appearance to bronze. Since

this plane isn't made of

iron, like the #41, it is somewhat malleable. Dropping it on a hard

floor won't

necessarily break it, like an iron one is apt to suffer.

Instead, the metal

will bend a bit before it breaks, so check for ones that

have been mistreated

by sighting down its skate - it should be perfectly

straight.

This plane, like the #41, can accept the same two fences as those that fit

the #41. However, the

fillister fence is cast of gun metal, and the ploughing

fence is cast from

iron. Never accept one that has two iron fences. As is the

case with the #41, the plane is most

often found with a single fence, and a missing fillister

bottom (it's also

fashioned from iron for this plane). There are

reproductions fences out there,

and they are rather easy to spot. They don't have the

detail that the original

does; the fine pebbled background on the portions that

loop up to meet the

holes for the arms is washed out and nearly smooth.

The earliest models have their background japanned

which gives the tool a

striking appearance with the machined, unpainted high spots.

Even the most

powertool hungry wood processer would find this plane a joy

to own. The humback

models do not have the pronounced hook above the top of the

handle, but it does

have a slight hook that sets it apart from the later

castings.

#43 Miller's Patent Adjustable Metallic Plow and Matching Plane, 1871-1895. *

The same basic

design as the #41

except that the plane doesn't have the fillister bed and

cutter. Therefore,

there is only one fence provided on the plane. The easiest

way to distinguish

this plane from the #41 is to look for the two screw

holes in the skate;

this model doesn't have them.

The same basic

design as the #41

except that the plane doesn't have the fillister bed and

cutter. Therefore,

there is only one fence provided on the plane. The easiest

way to distinguish

this plane from the #41 is to look for the two screw

holes in the skate;

this model doesn't have them.

The earliest models of this plane, the ones of the

humpback casting,

provided the fillister fence, with some slight modification,

as the standard

ploughing fence. Since the fillister fence has looping ends

to fit over the

fillister bed, which isn't supplied with this model, they

are filled in with

iron to give it a bit more strength. They were cast this

way, not modified

after the fact. Stanley introduced the familiar and shorter

ploughing fence

when the humpback casting was dropped for the later style

plane.

These planes aren't as common as the #41, but because they don't have

all the bells and

whistles as the #41, namely the fillister bed and fence, they don't

command as much money

as the #41

does.

#44 Miller's Patent Adjustable Metallic Plow

and Matching

Plane, 1871-1892. *

Same as the #42 except it is made

from gunmetal. The ploughing fence is cast from gunmetal

as well. This fence is

damn tough to replace if you need one. This is the rarest

of the four models of

Miller's ploughs.

Same as the #42 except it is made

from gunmetal. The ploughing fence is cast from gunmetal

as well. This fence is

damn tough to replace if you need one. This is the rarest

of the four models of

Miller's ploughs.

I can't say whether the filled-in fillister fence was

supplied as the

ploughing fence with this plane on the humpback models. I

suspect it was, but

that's not certain since this plane is rare enough as it is,

and the early

humpback models of any of these planes are rarer still. I've

yet to see an

example surface in a collection or show up for sale (public

or private).

[ START ] |

[ PREV ] | [ NEXT

] | [ END ]

[ HOME

]

Copyright

(c) 1998-2012 by Patrick A. Leach. All Rights Reserved.

No part may be

reproduced by any means without the express written

permission of the author.