The Superior Works: Patrick's Blood and Gore Planes #21 - #37

Quick Find: #21, #22, #23, #24, #25, #26, #27, #27 1/2, #28, #29, #30, #31, #32, #33, #34, #35, #36, #37

Stanley claimed that "Every Carpenter needs two or

more wood planes in

his kit, for rough outside work" and that "wood planes push

easier." Thus, these planes were offered as an alternative

to the metallic

planes. Furthermore, some guys preferred the feel of wood

against wood, like

that afforded by the old style wooden bench planes. But,

they also understood

the benefit of the patented adjustment features found on the

metallic planes.

Stanley made it possible for these guys to have their cake

and eat it, too, by

offering these planes.

There are many

different

sizes of these wood bottom planes, often called

transitionals (they bridged the

all wood and all metal designs), than there are of the metal

ones. Why? Because

patterns are not needed for wooden bodies like they are for

metal bodies. Thus,

the plane's body could practically be any size desired. The

18 different models

attest to this fact - all of them are different lengths and

widths. Guys could

also tailor their wooden plane to the exact length with

which they were

comfortable by sawing off the toe and/or heel.

There are many

different

sizes of these wood bottom planes, often called

transitionals (they bridged the

all wood and all metal designs), than there are of the metal

ones. Why? Because

patterns are not needed for wooden bodies like they are for

metal bodies. Thus,

the plane's body could practically be any size desired. The

18 different models

attest to this fact - all of them are different lengths and

widths. Guys could

also tailor their wooden plane to the exact length with

which they were

comfortable by sawing off the toe and/or heel.

Judging by the numbers still out there, these were

very popular planes, so

popular that many of Stanley's competitors decided to make

their versions of

wood bottom planes (makers such as Sargent, Union,

Birmingham, Siegley, etc.).

When sold originally, they were at a price somewhat less

than their iron

counterparts making it possible for the average Joe Meatball

of the day to

afford a plane that came equipped with the Bailey patented

features.

There are only a few

numbers that are generally considered anywhere near

collectible - the #21, #25, and #37. Of course, the

earliest versions of the planes, mainly the ones made by

Leonard Bailey himself

in Boston, are scarce and collectible. There are some late

production wood

bottom planes that have the Hand-y grip feature, similar

to that found on the

common metal block planes, milled into their wooden

bodies. These planes are

very rare.

There are only a few

numbers that are generally considered anywhere near

collectible - the #21, #25, and #37. Of course, the

earliest versions of the planes, mainly the ones made by

Leonard Bailey himself

in Boston, are scarce and collectible. There are some late

production wood

bottom planes that have the Hand-y grip feature, similar

to that found on the

common metal block planes, milled into their wooden

bodies. These planes are

very rare.

The last models to leave New Britain have unusually

tall knobs - it seems

that the high knob craze sweeping the metallic line of

planes found its way

onto these tried and true planes; the high knob versions are

rather scarce, and

the knob is fastened with a long wood screw, not the brass

nut on a threaded

rod used on the metallic planes.

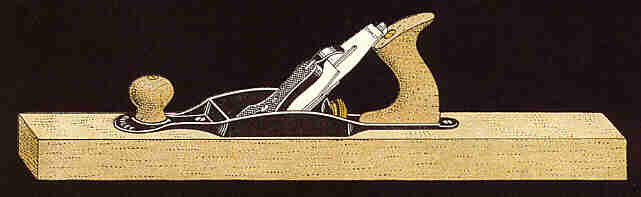

The basic design of these planes consists of a cast

iron frame that is screwed

onto a wooden body. The frog rests over a bridge in the

frame, the knob sits

atop the front of the frame, and the tote is screwed into a

raised boss cast

into the rear of the frame. The wood - knob, tote, and body

- are made of

beech, and often covered with a very heavy varnish that

practically obliterates

the wood's grain. The plane's number is stamped (incised)

into the toe, usually

along with the company's name and, on the earlier examples,

an eagle.

The knob is secured directly to the wooden body by

means of a regular wood

screw, so don't go thinking you can use the fastening means

(a threaded rod and

a slotted nut) as that found on the metallic planes as a

replacement. In fact,

there is little that can be salvaged from these planes to

use as parts on the

metallic planes and vice versa.

The tote does use the same fastening means as that

found on the metallic

planes. However, the tote is not secured as well on the

wooden planes. The

larger metallic planes have a small machine screw at the

front part of the

tote, while the smaller metallic planes have a raised nib

cast in the main

casting. Both of these features help to overcome any lateral

twisting of the

tote. The wooden planes do not have either of these

supplemental measures for

securing the tote. Perhaps Stanley felt they were

unnecessary since the wooden

planes are lighter than the metallic ones and the strain on

their (wooden)

totes wasn't as great as that on the metallic planes' totes.

Whatever the

reason, I've seen many totes on the wooden planes that are

very loose. The

totes on these planes are normally found cracked and broken.

The frog is

adjustable,

but in order to take advantage of this feature some

modification to the bed

must be made. Due to the design of the frog (it sort of

looks like the ones

used on the iron planes, but is shorter along its bed

length), in conjuction

with the use of wood as the body, the cutter can be

unsupported for a good

length when the frog is moved forward. The wood can't be

adjusted, but the frog

can, which means that the cutter will flex backward as the

plane is pushed

forward, likely chattering, when the frog's face is not

co-planar with the bed.

Even Stanley mentioned this shortcoming in their tool

propaganda. To overcome

this problem, Stanley recommended that a shim of cardboard

or veneer be glued

to the bed to make it co-planar with the face of the frog.

This remedy was

particularly useful when the sole became worn, which

inevitably increased the

width of the mouth necessitating that the frog be moved

forward to compensate

for the increase in the mouth's width.

The frog is

adjustable,

but in order to take advantage of this feature some

modification to the bed

must be made. Due to the design of the frog (it sort of

looks like the ones

used on the iron planes, but is shorter along its bed

length), in conjuction

with the use of wood as the body, the cutter can be

unsupported for a good

length when the frog is moved forward. The wood can't be

adjusted, but the frog

can, which means that the cutter will flex backward as the

plane is pushed

forward, likely chattering, when the frog's face is not

co-planar with the bed.

Even Stanley mentioned this shortcoming in their tool

propaganda. To overcome

this problem, Stanley recommended that a shim of cardboard

or veneer be glued

to the bed to make it co-planar with the face of the frog.

This remedy was

particularly useful when the sole became worn, which

inevitably increased the

width of the mouth necessitating that the frog be moved

forward to compensate

for the increase in the mouth's width.

On the earlier models of this class of planes, those

made prior to ca. 1915,

the screws used to hold the frog to the plane are wood

screws and have round

heads. These screws, over time, tended to strip the wood,

making it impossible

for the frog to be secured to the plane. You'll occasionally

see examples where

the screw holes have been plugged and then re-tapped.

Stanley addressed this

problem with their 1912 patent which called for brass

bushings to be screwed

and pinned into the wood, and to use flat-head machine

screws to secure the

frog to the bushings.

I often find the brass depth adjustment nut on these

planes to be difficult

to operate, especially on the smaller models. Reason being

that the cast iron

frame makes it difficult to get a good grip on the nut; you

can only turn the

nut at its top, unlike from all around it like you can on

the metallic models.

All these planes are

equipped with a unique style of lever cap. It operates just

like the lever cap

used on any common metallic bench plane, but its finish and

casting is

different. The lever cap has a stippled surface cast into it

and is japanned on

its top. The rivet to hold the lever cap spring is not

machined flat on the

surface. Instead, it's left proud and is rounded. At the

lowermost edge of the

lever cap, where it makes contact with the cap iron when it

is locked in place,

there is a machined decorative motif, similar to two

opposing reverse ogees.

This motif is not japanned but is machined smooth. The

earliest models of these

planes have lever caps that are smooth, but are also

japanned all over. I've

seen some of the early lever caps that have the corners

knocked off, down where

they bear upon the iron. Since the corners have japanning on

them, it appears

that this was intentional and was probably some feeble

attempt to make the

lever cap slide into the body easier without what normallay

are square corners

digging into the wooden body.

All these planes are

equipped with a unique style of lever cap. It operates just

like the lever cap

used on any common metallic bench plane, but its finish and

casting is

different. The lever cap has a stippled surface cast into it

and is japanned on

its top. The rivet to hold the lever cap spring is not

machined flat on the

surface. Instead, it's left proud and is rounded. At the

lowermost edge of the

lever cap, where it makes contact with the cap iron when it

is locked in place,

there is a machined decorative motif, similar to two

opposing reverse ogees.

This motif is not japanned but is machined smooth. The

earliest models of these

planes have lever caps that are smooth, but are also

japanned all over. I've

seen some of the early lever caps that have the corners

knocked off, down where

they bear upon the iron. Since the corners have japanning on

them, it appears

that this was intentional and was probably some feeble

attempt to make the

lever cap slide into the body easier without what normallay

are square corners

digging into the wooden body.

There really isn't too much that can go wrong with

these planes other than

the fact that they usually look like what you'd expect a

plane to look like

after leaving it on your local Interstate or railroad tracks

and letting it

suffer the ravages of heavy traffic flow. They are rugged

guys that served

their owners well. Other than the obvious casting breaks

about the frog or the

frame itself, the most common problem with these planes is

their soles. Through

repeated use, they become sole shot. You'll often find

examples that list to

one side, have been re-soled over their entire length, have

a length of metal

screwed into the sole, or have a piece let into their soles

to close their

mouths.

You can sometimes find the planes so riddled with

worm holes that they

resemble Bonnie and Clyde's last stand. Stay away from these

instant Uncle

Miltie's ant farms, or you're asking for trouble - hungry

worms like to do

roadtrips in their quest for other succulent woods, and

might decide to set up

shop in your Chelor's or Nicholson's.

These planes are very cheap (in price), and are worth

obtaining to practice

your restoration skills. A few caveats - the frogs of the

wood bottom planes

are not interchangable with the metallic planes, and vice

versa. Also, the cap

irons are not interchangeable. The slot in which the depth

adjusting fork

engages is located higher up, toward the top, of the cap

iron. If your plane's

iron can't be adjusted for a fine cut, you have a cap iron

from a metallic

plane. The later cap iron of this series of planes does not

have the 'hump'

formed in it, down where it covers the iron near its cutting

edge; it just

bends abruptly to make contact with the iron. You can also

sometimes find these

cap irons with two slots milled in them, one slot above the

other. These cap

irons were likely left-over stock, when the transitional

line went extinct, and

Stanley milled the lower slot so that they could be used on

the metallic

planes.

You might stumble

across

a transitional that has a bottom made of a wood other than

beech. These planes

were retrofitted by later day owners who decided to make

another bottom. I've

seen a laminated maple and mahogany one that looked rather

cool. Since

scribbling this description (1997), three very rare 'custom'

transitionals have

surfaced where the body is a composite of rosewood and

boxwood; the rosewood,

which acts as the sole, is dovetailed into a chunk of

boxwood. These planes are

definitely Stanley-made as the early company logo (the crude

eagle logo) is

stamped into the endgrain of both the rosewood and boxwood.

The totes and knobs

of these planes are also fashioned from rosewood. These

planes may have been a

custom order or were purposely made for display at an

exhibition of some sort.

Regardless of why they are made, they are striking looking.

You might stumble

across

a transitional that has a bottom made of a wood other than

beech. These planes

were retrofitted by later day owners who decided to make

another bottom. I've

seen a laminated maple and mahogany one that looked rather

cool. Since

scribbling this description (1997), three very rare 'custom'

transitionals have

surfaced where the body is a composite of rosewood and

boxwood; the rosewood,

which acts as the sole, is dovetailed into a chunk of

boxwood. These planes are

definitely Stanley-made as the early company logo (the crude

eagle logo) is

stamped into the endgrain of both the rosewood and boxwood.

The totes and knobs

of these planes are also fashioned from rosewood. These

planes may have been a

custom order or were purposely made for display at an

exhibition of some sort.

Regardless of why they are made, they are striking looking.

Examples of these planes in succulently mint

condition are very difficult to

find, even more so in their original boxes. The longer

planes were shipped

wrapped in brown paper with a label afixed on the paper.

Planes in mint

condition can command a real premium, so if you find one

that's never been

used, sell it and take the proceeds to buy 100 ones that

have been rode hard

and put away wet.

A certain plane sect, located in the northeast,

practices a bizarre and

ritualistic ceremony where transitional planes are set

aflame a la a funeral

pyre. Whether it's in homage to Leonard Bailey, to appease

the spirit of Justus

Traut, or is symbolic of the sect's mission in life to turn

old tools into

cash, no one knows for certain. Regardless, it's a sight to

behold, and not to

be missed, given the opportunity to witness a Trans-Ferno

immolation in person.

And, no, it's not done under the anonymity of a white hood.

#21 Smooth plane 7"L, 1 3/4"W, 2 1/2lbs, 1870-1917. *

Contrary to most things in life, smaller is better when collecting bench planes, and this model is no exception. It's not rare, by any stretch of the imagination, just popular with collectors for the same reason the #2 is popular with them - they are both 7" long.

This plane, and those that follow up to and including

the #25, never had a tote. These

planes are simply too

short for a tote to fit on them. To provide for a

comfortable grip, the rear of

the cast iron frame is rounded allowing it to fit into the

palm of the hand

easily.

#22 Smooth plane 8"L, 1 3/4"W, 2 1/2lbs, 1870-1943.

This model has been observed with the Hand-y grip feature milled into the sides of the bottom, toward the rear. A crafty woodworker could easily duplicate this, so be very careful if you're about to cough up the megabucks it takes to own one.

#23 Smooth plane 9"L, 1 3/4"W, 2 1/2lbs, 1870-1918.

#24 Smooth plane 8"L (9"L 1922 on), 2"W, 2 7/8lbs, 1870-1943.

The increase of this plane's length to 9" in 1922 probably reflects the demise of the #23, which probably should have come equipped with a 2" wide iron in the first place. It took Stanley nearly 50 years to realize this.

#25 Block plane 9 1/2"L, 1 3/4"W, 2 1/2lbs, 1870-1923. *

This is a funky little guy. It is a block plane technically, since its cutter is bevel side up. Its cutter is bedded at 35 degrees, which is very steep for a plane of its function. So why is it so steep? To allow the plane to use the Bailey cutter depth adjustment feature on a wood bottom plane - there simply isn't enough room for these features if the cutter were put at a lower pitch.

This plane has the same plate that screws onto the

cutter as that used on

the #9

(see this one for an image of the plate), #11, #11 1/2, and #164. This plate is similar

to the regular cap iron (for

bevel side down planes) where the slot in it permits the

adjusting fork to

engage and then allows adjustment. Make sure this plane

has the plate, and not

a replacement cutter and cap iron taken from a similar

width bench plane. Many

times you'll find these planes with a replacement cutter

and a conventional cap

iron where the bevel is oriented downward.

#26 Jack plane 15"L, 2"W, 3 3/4lbs, 1870-1942.

The workhorse of the entire series, I see more of these, and the #27, than any others.

#27 Jack plane 15"L, 2 1/8"W, 4lbs, 1870-1918.

This plane and the #27 1/2 both have irons that are non-standard widths and do not have equivilent width irons in the metallic planes. This plane's iron, at 2 1/8" wide, might be considered by some to be an odd dimension, but when this plane made its debut bench plane irons were commonly sized by the 1/8".

#27 1/2 Jack plane 15"L, 2 1/4"W, 4 3/4lbs, 1898-1934.

Hey, if Stanley can make a fractional metallic bench plane, they surely could do the same with the wood bottom. And, they did, but they never delved into the 1/4's like they did with the bench and block planes. Yow, did they pull some stupid stuff! Maybe they foresaw the rabid collectors coming down the pike?

The iron on this plane is often pilfered for the more

valuable early models

of the #5 1/2 and #605

1/2 (and their

corrugated versions) as replacements.

Stanley made a blunder when they designed these early

versions of the metallic

planes, and it's common to find these two planes with

irons that have the later

notched rectangle logo.

While certainly not rare, this plane is the most

difficult to find of the

common transitionals.

#28 Fore plane 18"L, 2 3/8"W, 5 1/2lbs, 1870-1943.

Burn...

#29 Fore plane 20"L, 2 3/8"W, 6 1/4lbs, 1870-1918.

Baby...

#30 Jointer plane 22"L, 2 3/8"W, 6 1/4lbs, 1870-1918.

Burn...

#31 Jointer plane 24"L, 2 3/8"W, 6 1/2lbs, 1870-1943.

Trans-...

#32 Jointer plane 26"L, 2 5/8"W, 7 5/8lbs, 1870-1934.

itional...

#33 Jointer plane 28"L, 2 5/8"W, 8 3/8lbs, 1870-1918.

Inferno!

#34 Jointer plane 30"L, 2 5/8"W, 8 1/2lbs, 1870-1918.

The longest plane Stanley produced. It's not a very common plane, but its appeal was probably limited due to its size for the same reason that one doesn't find 30" long wooden jointers in great numbers. Still, examples in good condition are somewhat scarce, which makes some Stanley collectors foam at the mouth.

#35 Smooth plane 9"L, 2"W, 3 1/4lbs, 1870-1942.

This

smoothing plane, as well as

the #36, has a

tote. How can this plane, whose length is equal to the #23, have a tote whereas

the #23 can't?

It's simple - this plane is designed with a step, often

called a razee, at its

rear. The wood is stepped down, and the cast iron frame is

made to follow the

step. This design increased the amount of space directly

behind and under the

cutter, making it possible to equip the plane with a tote.

It was a very

popular feature, making this transitional smoother one of

the most commonly

encoutered.

This

smoothing plane, as well as

the #36, has a

tote. How can this plane, whose length is equal to the #23, have a tote whereas

the #23 can't?

It's simple - this plane is designed with a step, often

called a razee, at its

rear. The wood is stepped down, and the cast iron frame is

made to follow the

step. This design increased the amount of space directly

behind and under the

cutter, making it possible to equip the plane with a tote.

It was a very

popular feature, making this transitional smoother one of

the most commonly

encoutered.

Check the cast iron frame, where it steps down for

any signs of repairs or

cracks. This area is prone to breakage, as is the overhang

onto which the tote

fastens.

#36 Smooth plane 10"L, 2 3/8"W, 4lbs, 1870-1934.

This is the same general design as the #35, only it's one inch longer and has a wider iron. Hey, this is like the #4 1/2 Light since it's made of wood. Wonder why they didn't make the #5 1/2 Light? Because they made the #37.

#37 Jenny plane 13"L, 2 5/8"W, 5lbs, 1870-1923. *

The name "Jenny" is unique to this plane. Since this plane is slightly shorter than the metallic jack plane, a parallel naming was taken from the asses (donkies). "Jack" is a commonly used when referring to the male donkey, and "Jenny" is a name sometimes used for the female donkey. The jenny is smaller than the jack, hence the naming of the planes. All of this is really conjecture, but it sure provides some filler for an otherwise bland series of planes.

This plane also has the step in the wood, with the

cast iron frame following

the contour of the wood, though not as pronounced as the #35 and #36. This isn't a very

common plane, but Stanley saw

fit to offer it for some 50 years.

[ START ] |

[ PREV ] | [ NEXT

] | [ END ]

[ HOME

]

Copyright

(c) 1998-2012 by Patrick A. Leach. All Rights Reserved.

No part may be

reproduced by any means without the express written

permission of the author.