The Superior Works: Patrick's Blood and Gore Planes #602 - #608C

Quick Find: #601, #602, #602C, #603, #603C, #604, #604C, #604 1/2, #604 1/2C, #605, #605C, #605 1/4, #605 1/2, #605 1/2C, #606, #606C, #607, #607C, #608, #608C

In a world where good

enough usually ain't good enough, Stanley decided to produce

another series of

metal bench planes, called Bed Rock planes. These planes

are, for all intents

and purposes, nothing but a variation of the more popular

Bailey series. They

all have an adjustable frog, the brass depth adjustment

knob, the lateral

lever, a lever cap, rosewood knob and tote, etc., just like

the Bailey's. The

key difference between the two designs is found in the way

the frog mates with

the bottom casting. For such a seemingly minor difference,

the Bed Rock planes

were offered at a premium over the Bailey's, and it was a

design that never

seemed to be very static nor nearly as popular as Stanley's

wildly successful

Bailey line.

In a world where good

enough usually ain't good enough, Stanley decided to produce

another series of

metal bench planes, called Bed Rock planes. These planes

are, for all intents

and purposes, nothing but a variation of the more popular

Bailey series. They

all have an adjustable frog, the brass depth adjustment

knob, the lateral

lever, a lever cap, rosewood knob and tote, etc., just like

the Bailey's. The

key difference between the two designs is found in the way

the frog mates with

the bottom casting. For such a seemingly minor difference,

the Bed Rock planes

were offered at a premium over the Bailey's, and it was a

design that never

seemed to be very static nor nearly as popular as Stanley's

wildly successful

Bailey line.

Since the primary difference between the two models

is in their frog

designs, most of what follows is paid to that minutiae. If

you don't wanna be

stuck in the quagmire of frog design, best find something

else upon which to

ponder, like modern day uses of the amazing fiberboard

planes, the #193A, #194, etc.

The Bailey frog underwent several modifications in an

attempt to make it

seat better, and cheaper (each and every frog, and its

receiving part of the bottom

casting, had to be machined for a proper fit). By about

1900, the frog design

had pretty much evolved into the design that most of us

handtool

fundamentalists recognize - the angled bottom that mates to

the bottom casting

at two areas, one along the rear of the mouth and the other

at a raised

crossbar that spans the interior width of the bottom

casting. In other words,

the frog does not mate with the bottom casting over the

entire area of the

frog's bottom. So someone at Stanley, Justus Traut (the dude

who gave us the #45, et al),

sniffed out a marketing opportunity here. What if a plane

were offered that had

a frog design where its entire bottom mated with a

corresponding area in the

bottom casting? There's sure to be megabucks reaped with

this design. Or so

Stanley thought. The series was a dud when compared to the

numbers of Bailey

planes sold, and it did have its bright spots, but it,

like so many other

attempts to build a better mousetrap, also went belly-up

after some 40 years of

production.

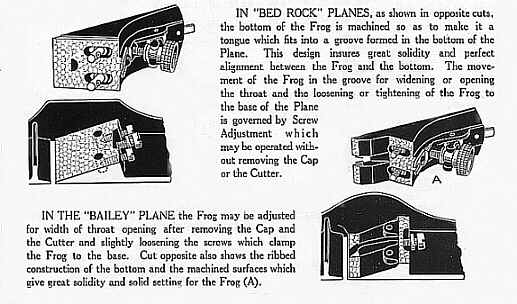

First,

the

basic frog design of the Bed Rock needs explanation. The

bottom casting has

a sloped and machined area onto which the frog seats, for

its entire length.

The frog itself only differs from the conventional Bailey

design in that its

bottom is flat and fully machined. A side view of the frog

yields a wedge-like

appearance. There is one other subtle detail about the frog

design - the frog's

bottom forms a broad and flat tongue, which fits into the

bottom casting's broad

and flat groove. This was provided to prevent the frog from

shifting side to

side, and guaranteed that the frog would move at a right

angle (to the mouth)

when the frog was adjusted. So there you have it, a frog

that mates with the

bottom casting over its (the frog's) full length and is

self-centering as well

(this design remained static during the entire production of

the Bed Rock

series). Sure woulda made me want to spend the extra 50

cents (average price

difference) to buy one of these babies back ca. 1900.

First,

the

basic frog design of the Bed Rock needs explanation. The

bottom casting has

a sloped and machined area onto which the frog seats, for

its entire length.

The frog itself only differs from the conventional Bailey

design in that its

bottom is flat and fully machined. A side view of the frog

yields a wedge-like

appearance. There is one other subtle detail about the frog

design - the frog's

bottom forms a broad and flat tongue, which fits into the

bottom casting's broad

and flat groove. This was provided to prevent the frog from

shifting side to

side, and guaranteed that the frog would move at a right

angle (to the mouth)

when the frog was adjusted. So there you have it, a frog

that mates with the

bottom casting over its (the frog's) full length and is

self-centering as well

(this design remained static during the entire production of

the Bed Rock

series). Sure woulda made me want to spend the extra 50

cents (average price

difference) to buy one of these babies back ca. 1900.

Someone else at Stanley, Edmund Schade, invented a

little gizmo that found

permanent use on all Bed Rocks and was latter added to the

Bailey line. It's a

lucky thing, too, that he did invent this otherwise it

probably would have been

impossible for Stanley to justify the Bed Rocks; i.e., it

may have been more

difficult to convince the tool-buying masses that the

difference between the

two lines was of any great significance. This little gizmo,

first offered on

the Bed Rock planes from their inception, is a little frog

adjustment screw

that engages a captive fork secured to the back of the frog.

This feature was

more of a gimmick than anything else, but it soon found

favor amongst hand

planers across America. By giving the screw a turn, the frog

moved either

forward or backward. Frog screwing, thought the stuff of the

plane lover's

fancy, soon swept America, and it was inevitable that this

mechanism would be

added to the Bailey design, which it was ca. 1910. It really

is a wonder how

planedudes survived without this feature for the previous

30/40 years, but they

did. The true merit of this feature was proved when, during

WWII, some of the

Bailey planes were offered without this. Think Stanley's

complaint department

had its phones ringing off the hook over this?

The introduction of

the

frog adjusment screw to the Bailey series left the Bed Rocks

without any real

distinguishing pizazz, other than the bright red label used

on the boxes of the

planes, as the lever cap still had to be removed to gain

access to the screws

(that secured the frog to the main casting) in order to

adjust the frog in the

first place. To address this, the New Britain stinktank (tm)

had to come up

with some other gimmick to differentiate the Bed Rocks from

the Baileys, and

what they decided upon was the capability to adjust the frog

without removing

the lever cap and iron. Hey, think how much Joe Meatball's

daily existence was

bettered simply by saving him from having to remove the

lever cap, and then

backing off the two frog securing screws to adjust the frog,

something that's

done at least once or twice a month or two. But, guess what?

This swell feature

had already been solved a few years earlier by one of

Stanley's main

competitors, Sargent, located in New Haven, CT, just a short

trip south of New

Britain. On July 3, 1906, John Shaw received a patent for

frog adjustment

without having to remove the lever cap and iron assembly.

This innovation was

soon 'copied' by Edmund Schade, who came up with another way

to accomplish the

same function, on March 14, 1911. Stanley surely must have

perceived some

threat from Sargent over this, although the Sargent line of

planes

incorporating Shaw's patent aren't all that common. For a

detailed look at

Shaw's patent, click here.

The introduction of

the

frog adjusment screw to the Bailey series left the Bed Rocks

without any real

distinguishing pizazz, other than the bright red label used

on the boxes of the

planes, as the lever cap still had to be removed to gain

access to the screws

(that secured the frog to the main casting) in order to

adjust the frog in the

first place. To address this, the New Britain stinktank (tm)

had to come up

with some other gimmick to differentiate the Bed Rocks from

the Baileys, and

what they decided upon was the capability to adjust the frog

without removing

the lever cap and iron. Hey, think how much Joe Meatball's

daily existence was

bettered simply by saving him from having to remove the

lever cap, and then

backing off the two frog securing screws to adjust the frog,

something that's

done at least once or twice a month or two. But, guess what?

This swell feature

had already been solved a few years earlier by one of

Stanley's main

competitors, Sargent, located in New Haven, CT, just a short

trip south of New

Britain. On July 3, 1906, John Shaw received a patent for

frog adjustment

without having to remove the lever cap and iron assembly.

This innovation was

soon 'copied' by Edmund Schade, who came up with another way

to accomplish the

same function, on March 14, 1911. Stanley surely must have

perceived some

threat from Sargent over this, although the Sargent line of

planes

incorporating Shaw's patent aren't all that common. For a

detailed look at

Shaw's patent, click here.

Schade's novel way of frog adjusting was accomplished

by the addition of two

frog clamping screws that flank either side of the frog

adjusting screw. Each

of these screws is pointed (on the end without the slot) and

engages two pins

which have a corresponding conical depressions milled into

them. The pins fit

through the frog and into the bottom casting, and have no

holding power by

themselves. The two screws apply a downward force on the

pins when they are

tightened, thus locking the frog securely in position. By

backing off the

screws, the pressure on the pins is relieved, and the frog

can be moved forward

or backward by turning the frog adjustment screw. It's a

neat and efficient

frog adjusting mechanism, but its real merit is somewhat

questionable since

frog adjusting is not something done with any regularity,

like, say, adjusting

the plane's set (depth of cut). Click

here to see a

blow-by-blow description from the hands of

Stanley's propaganda machine.

And speaking of the plane's set, that's exactly what

changes whenever the

frog is adjusted forward or backward. Since the frog and its

mating surface are

inclined toward the mouth, the frog moves closer to or

farther from the mouth

as it's adjusted forward or backward respectively. With the

iron secured to the

frog, it follows, then, that the iron likewise moves closer

to or farther from

the mouth. Adjusting the frog forward increases the set, and

adjusting it

backward decreases the set. Now, granted, the amount by

which the set is

changed is small, but when using a smoother for finish work,

or using any bench

plane on a very hard wood, the slightest change in the set

needs to be

accounted for after the frog is adjusted, so there is really

no true reduction

in the number of adjustments to the plane as the frog is

repositioned. On the

plus side, however, you have another mechanism for adjusting

the iron's set

should you ever break the adjusting fork - who would have

guessed that Stanley

invented fault tolerant planing without their ever realizing

it?

At the same

time the new frog securing screws were added, the bottom

casting itself

underwent a change in appearance. Where the casting rises up

around the frog,

on either side of the frog, the tops are lopped off flat,

instead of the normal

round sides found on the earlier Bed Rocks and the Baileys.

This change was

advertised as adding significantly to the strength and

stiffness of the plane

as well as affording an increased area when the plane is

used on its sides, a

claim that is rather dubious as Bed Rocks can be found with

cracks about the

main casting in this supposed strengthened area.

At the same

time the new frog securing screws were added, the bottom

casting itself

underwent a change in appearance. Where the casting rises up

around the frog,

on either side of the frog, the tops are lopped off flat,

instead of the normal

round sides found on the earlier Bed Rocks and the Baileys.

This change was

advertised as adding significantly to the strength and

stiffness of the plane

as well as affording an increased area when the plane is

used on its sides, a

claim that is rather dubious as Bed Rocks can be found with

cracks about the

main casting in this supposed strengthened area.

WWII spelled the end for these planes, as it did for

many other tools that

Stanley had offered for years. Most of these tools were on

life support anyway,

and the war was the final nail in the coffin, the Bed Rocks

included.

Other than the stuff I list above, there are some

other telltale ways to

date your Bed Rocks. Chief among the other ways is the lever

cap and its

embossing. The earliest models have "STANLEY/R. & L.

Co./BED ROCK" cast in

three separate lines (that's what the

/ means). Starting around 1910, the lever caps have "STANLEY/BED

ROCK" in two lines. A

few years

later, just "BED ROCK"

is cast. From ca. 1925 onward, "STANLEY" is all that appears. There

are other

differences in the models, but they are minor in the grand

scheme of things

here.

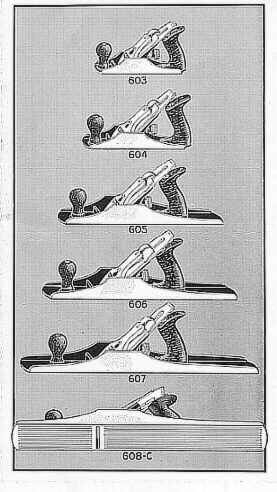

What follows is the actual Bed Rock models. These

parallel the Bailey planes

in function. As with those planes, the "C" designation means

that the

plane has corrugations in the sole (for reducing friction as

the plane forms a

vacuum with the wood); the "C" doesn't appear on the plane.

These

planes can suffer the same general damage that the Baileys

can, and for a

description of that damage, refer to the #3 of the Bailey series. The Bed

Rocks can also show

damage about the frog clamping screws - sometimes you can

find them with their

slots broken in which case you'll need to find

replacements.

Only three of the planes in the series are considered

anywhere near scarce,

the #602, #602C, and the #605 1/4. However,

there is a premium paid to acquire any of the planes when

buying from dealers.

This, in the author's opinion, is due to the hype found

within some books and

articles. If you want a better plane, and one that's less

costly, go with the

Type 2 Bailey's. These are the best planes what Stanley

ever did make.

#601

Smooth plane, 5

3/4L, 1 1/4"W, 1 1/4lbs, 2000-?.

Stanley never made one, but The Superior Works is. You can buy one yourself by

clicking here.

#602 Smooth plane, 7"L, 1 5/8"W, 2 1/4lbs, 1898-1942. *

There's a lot of stuff going on below the frog of the later Bed Rocks, and it's very apparent on this, the smallest planes of the series, when you try to jam a screwdriver down there to screw around with the frog. Still, they are popular planes with collectors and users of today, probably owing that to their unique look where everything is scaled down to make the plane look rather cute.

#602C Smooth plane, 7"L, 1 5/8"W, 2 1/4lbs, 1898-1918. *

Be careful for counterfeit corrugations on this one. It's one of Stanley's scarcer planes, especially in the round top configuration, which opens it up for the crafty tool artisans to apply their handiwork.

#603 Smooth plane, 8"L, 1 3/4"W, 3 1/4lbs, 1898-1943.

#603C Smooth plane, 8"L, 1 3/4"W, 3 1/4lbs, 1898-1935.

#604 Smooth plane, 9"L, 2"W, 3 5/8lbs, 1898-1943.

#604C Smooth plane, 9"L, 2"W, 3 5/8lbs, 1898-1935.

#604 1/2 Smooth plane, 10"L, 2 3/8"W, 4 3/4lbs. 1898-1935.

While many users fancy this plane as a fine worker due to its heft, they aren't especially enamoured with the price tag that usually accompanies the tool. If it's heft you want, and you have the money to buy this guy, save your lunch money for a few months more, and buy a real killer smoothing plane, an English infill. You'll never regret it as they far out-perform any Bed Rock plane.

#604 1/2C 10"L, 2 3/8"W, 4 3/4lbs, 1898-1935.

#605 Jack plane, 14"L, 2"W, 4 1/2lbs, 1898-1942.

Probably the most commonly encountered size of the Bed Rock series.

#605C Jack plane, 14"L, 2"W, 4 1/2lbs, 1898-1935.

#605 1/4 Jack plane, 11 1/2"L, 1 3/4"W, 4lbs, 1925-1943. *

This plane is one of the

scarcest of the entire Bed Rock series.

This plane is one of the

scarcest of the entire Bed Rock series.

Note that this model can't be found with the earlier

round sides as it

wasn't introduced until after the series underwent the

design change of the

flat top side and the frog clamping screws.

Because the #605 1/4 is the Bed Rock

equivalent of the Bailey #5 1/4, which was a plane favored by

the trade schools for

manual training, and because the Bed Rock planes, plane

for plane, were sold at

a premium price over the Bailey equivalents, it follows

that these planes

didn't sell well to the trade schools, thus accounting for

their scarcity.

However, the planes were bought by some school districts,

and it's possible (or

was possible) to find stashes of these planes in schools.

Stanley never offered a corrugated version of this

plane in their catalogs.

This doesn't mean that they wouldn't possibly make one upon

special request, as

Stanley did for other stuff, but if you ever see one, I'd be

damn sure it was

legit before I plopped down more than $100 for it.

As an aside, I once bought over 200 of these from a

fellow who found a pile of them in Milwaukee. That city was

closing its trade schools, and a hoarde, rivaling the

Staffordshire Anglo-Saxon hoarde, was found. And, I didn't

even buy them all, as the guy sold many to other guys!

#605 1/2 Jack plane, 15"L, 2 1/4"W, 6

1/2lbs,

1898-1935.

Pay attention to this, and the corrugated version's, iron. It's non-standard with the others in the series, and if you're in need of a replacement, you'll have to snag it from a similar vintage #5 1/2 or a #27 1/2.

#605 1/2C Jack plane, 15"L, 2 1/4"W, 6 1/2lbs, 1898-1935.

#606 Fore plane, 18"L, 2 3/8"W, 7 3/8lbs, 1898-1941.

The nearest Stanley got to designating a single plane with the sign of the beast, 666. Push one of these suckers backward over some oak and you'll hear Ozzy Osborne chanting "norm is god, norm is god, all hail norm, prince of darkness and everything that's wrong with the world!"

#606C Fore plane, 18"L, 2 3/8"W, 7 3/8lbs, 1898-1934.

Push this one backward, and you'll hear Slim Whitman caterwaul "Shake Your Groove Thing." Yeah, yeah.....

#607 Jointer, 22"L, 2 3/8"W, 8 3/4lbs, 1898-1943.

#607C Jointer, 22"L, 2 3/8"W, 8 3/4lbs, 1898-1935.

#608 Jointer, 24"L, 2 5/8"W, 9 3/4lbs, 1898-1940.

#608C Jointer, 24"L, 2 5/8"W, 9 3/4lbs, 1898-1935.

[ START ] |

[ PREV ] | [ NEXT ] | [

END ]

[ HOME

]

Copyright

(c) 1998-2012 by Patrick A. Leach. All Rights Reserved.

No part may be

reproduced by any means without the express written

permission of the author.