The Superior Works: Patrick's Blood and Gore Planes #100 1/2 - #140

Quick Find: #100 1/2, #101, #101 1/2, #102, #103, #104, #105, #110, #112, #113, #118, #120, #122, #127, #129, #130, #131, #132, #135, #140

#100 1/2 Block plane, 3 1/2"L, 1"W, 3/8lb, 1936-1962.

This little plane is

identical to the #100, with its squirrel tail

handle, but differs in that

its sole is convex both toe to heel (12" radius) and side

to side

(7/8" radius). The plane was advertised as being useful

for model and

pattern makers.

This little plane is

identical to the #100, with its squirrel tail

handle, but differs in that

its sole is convex both toe to heel (12" radius) and side

to side

(7/8" radius). The plane was advertised as being useful

for model and

pattern makers.

Like the #100 and the #101, the lever cap was

painted red from 1941 through final production. The main

casting is japanned,

with the exterior machined.

Like the #100 and the #101, the lever cap was

painted red from 1941 through final production. The main

casting is japanned,

with the exterior machined.

This plane, as well as the #100 and #101, has a small, circular

depression, in which to

place your index finger during use, at the toe. It also

has a hole drilled in

its handle so that it can be hung on a nail.

Stanley actively solicited ideas from tradesman, and

others, for tools that

they could make. This plane is an example of one such plane,

and in an early

Stanley advertisement for the plane, they specifically

mention this fact:

|

This

modelmaker's convex plane fills Like many other

modelmakers, |

#101 Block plane, 3 1/2"L, 1"W, 1/4lb, 1877-1962.

Same style of plane as

the #100

and #100 1/2. However, this plane has no rear handle like the

two previous. The

plane was designed for household use, and lighter work. It

was originally sold

in toy tool chests, but gained such popularity that it was

soon advertised as a

craftsman's tool.

Same style of plane as

the #100

and #100 1/2. However, this plane has no rear handle like the

two previous. The

plane was designed for household use, and lighter work. It

was originally sold

in toy tool chests, but gained such popularity that it was

soon advertised as a

craftsman's tool.

The earliest model of the plane has the top of its

cutter rounded in a

slight arc from side to side. The later model has the top of

its cutter

finished in an angular fashion, like those of the common

bench planes. Many of

these planes have been modified by users to do custom tasks,

with the most

common modification being its conversion to a bull nose

function, similar to

the #101 1/2.

This plane is japanned over its entire main casting,

except for the sole.

The lever cap is also japanned, but starting around 1941 it

was painted red.

The last models of the plane are painted grey and have a red

lever cap, and

very much resemble the Millers Falls' version of the plane.

Many manufacturers made knock-offs of this plane,

with Sargent&Co.

having cranked out a load of them under their model number

104, which is

usually found cast into the tool right behind the cutter.

Another company even

made an aluminum version of this tool, probably trying to

cash-in on Stanley's

incrediblely successful aluminum plane products. Er, on

second thought,

probably not.

#101 1/2, Block plane, 3 1/2"L, 1"W, 1/4lb, 1881-1928. *

This is a very scarce

plane, which was never offered in any of Stanley's tool

catalogs, but was

offered in the catalogs of the major tool dealers in the

United States and

England. In fact, it's in England where most of these little

guys are found.

This is a very scarce

plane, which was never offered in any of Stanley's tool

catalogs, but was

offered in the catalogs of the major tool dealers in the

United States and

England. In fact, it's in England where most of these little

guys are found.

The plane is nothing but a bull nose version of the #101, with one very important

difference - there is a

small finger rest cast into the bridging member of the

casting that spans the

width of the plane, forward of the cutter, giving the

plane the appearance of

Fudgy the Whale sticking his tongue out, when viewed from

the side. This is

very important to remember, if you are a collector, since

the scum of the human

gene pool will grind the front of the #101 off, and try to pass it off as

an original example.

Would have been a nice try, except that the plane doesn't

measure up to the

length of a true #101 1/2.

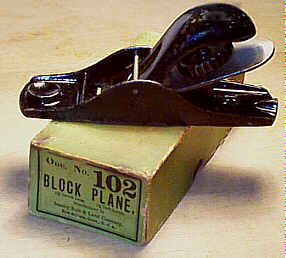

#102 Block plane, 5 1/2"L, 1 1/4"W (1 3/8", 1914 on (1 5/16, 1962), 7/8lb, 1877-1962.

This is a cheap (both

price and construction) block plane, with no adjustment

mechanism. A

featureless cutter sits over a raised, inclined projection

of the bottom

casting. A rod spans the side of the plane, under which a

lever cap is secured.

The lever cap has a large metal wheel on its underside,

which, when turned,

puts downward pressure on the cutter, directly below it. The

casting that

receives this wheel, underneath the lever cap, is sometimes

broken. If it is,

don't worry, this is a common and cheap enough tool that you

can find another.

But, I think they are junk, so why not trash it or give it

to your dog as a

chew toy, instead?

This is a cheap (both

price and construction) block plane, with no adjustment

mechanism. A

featureless cutter sits over a raised, inclined projection

of the bottom

casting. A rod spans the side of the plane, under which a

lever cap is secured.

The lever cap has a large metal wheel on its underside,

which, when turned,

puts downward pressure on the cutter, directly below it. The

casting that

receives this wheel, underneath the lever cap, is sometimes

broken. If it is,

don't worry, this is a common and cheap enough tool that you

can find another.

But, I think they are junk, so why not trash it or give it

to your dog as a

chew toy, instead?

There is no front knob, but there is a nice circular

depression in which you

can place your index finger during use. The plane is

japanned over the entire

main casting, except for the sole. Later examples of the

tool can be found with

a grey paint on the lever caps.

The first model of the plane has a solid lever cap,

whereas the later model

has an opening in the area where it engages the rod. Who

cares? They're both

junk.

#103 Block plane, 5 1/2"L, 1 1/4"W, (1 3/8", 1914 on), 7/8lb, 1877-1950.

This is the same plane

as the #102, but

it has a cheesy lever adjustment mechanism. This mechanism

is held captive in

the raised projection mentioned in the #102 description. The lever grips

grooves machined into

the underside of the cutter. Like the #102, a circular depression is cast

into the toe of the

plane to provide a finger rest. The iron is pitched at 20

degrees.

This is the same plane

as the #102, but

it has a cheesy lever adjustment mechanism. This mechanism

is held captive in

the raised projection mentioned in the #102 description. The lever grips

grooves machined into

the underside of the cutter. Like the #102, a circular depression is cast

into the toe of the

plane to provide a finger rest. The iron is pitched at 20

degrees.

The first model of this plane, illustrated here, is a

bit different - it has

a turned, wooden (fruitwood) front knob that screws onto a

thread boss of the

main casting. The knob is often replaced, missing, or split.

It has

"103" cast into the plane, not embossed (raised numbers), at

the

heel. The iron has the company name stamped in an arch at

the heel of the iron,

and directly below that is the 1876 patent date. This model

of the plane is

rather scarce and is collectible, but it's still a piece of

junk when compared

to the better block planes, equipped with all the bells and

whistles.

#104 Smooth plane, 9"L, 2 1/8"W, 3 1/8lbs, 1877-1918.

This is the first in a series (interrupted though it is) of cheaper bench planes, which were aimed at manual training and home handymen. This, and the #105, have steel bottoms, while the others in the series have wooden bottom. The steel bottom design is much thinner than the cast Bailey bottoms. Thus, they are lighter in weight than the corresponding sizes of the Baileys. One of the later catalog references to them states that the planes are practically unbreakable and that they are particularly useful for outdoor and rough work.

The bottoms are a composite construction. There is a

U-shaped main portion,

which corresponds to the main casting of a cast iron Bailey,

onto which are

rivetted a piece forward of the mouth, to carry the knob,

and piece behind the

mouth, to carry the 'frog' and the tote. The piece behind

the mouth has four

projections aranged in a square. The two projections nearest

the mouth are

shorter than those farthest from the mouth. Both are

'bevelled' so that they

can receive the backside of the iron. These projections are

cast iron and are

not adjustable; if any of them are cracks or broken, you're

pretty much S.O.L.

trying to fix them unless you're good at welding. Between

the projections and

running to the heel of the plane is a hump on the rivetted

piece. Rosewood is

used for the tote and knob, and the tote on this plane is

unique in that it has

a concave bottom to fit over the aforementioned hump.

The unmistakable lever cap has a Liberty Bell, with

the number

"76", cast into it. The reason why, is left as an exercise

for the

reader. The planes are often referred to as "Liberty Bells"

by the

tool collecting boys. Again, the reason why is left as an

exercise for the

reader.

The lever cap is of the common cheaper style, where

it's activated by a

thumb screw and sits under a rod, peened into the cheeks of

the plane. The

lever cap screw is cast with heavy knurling about it. The

screw is sometimes

japanned and sometimes nickel plated (it's more often

japanned), with the lever

cap entirely japanned.

The cutter is adjustable for depth by means of a

two-pronged lever held

captive between the projections that the iron rests upon. On

the business end

of the lever is a pin-like projection, which engages a

depression in the bottom

of the cap screw. Thus, this plane's cap screw is different

from that of the

Bailey design, so you should check that it's proper. The

screw is much smaller

than the Bailey's, and has a noticeable depression on the

slotted side. There

is no lateral adjustment mechanism.

Check that the cap iron is original. Since the tool

has its own cheaper

mechanism for adjusting the set, it also has its own cap

iron, which isn't

slotted like it is for the Bailey patent planes.

The planes are very rugged, and there is little that

can go wrong with them,

from a design standpoint. However, most of them suffered

harsh treatment, and

show it, usually with cracked totes and pitted soles. Check

the adjustment

lever, and its linkages, for breakage.

#105 Jack plane, 14"L, 2 1/8"W, 3 7/8lbs, 1877-1918.

Same as the #104, except that it is a jack size plane.

#110 Block plane, 7 1/2"L (7", 1917 on), 1 3/4"W (1 5/8", 1909 on), 1 3/8lbs, 1876-1973.

This was a very popular

block plane. It is like the #102, except it's longer. But, it's

still a cheap piece

of junk when compared to Stanley's other block planes.

There is no adjustment

mechanism provided on the plane, and proper irons have

backsides that are

without any notches; i.e. they are featureless and flat.

This was a very popular

block plane. It is like the #102, except it's longer. But, it's

still a cheap piece

of junk when compared to Stanley's other block planes.

There is no adjustment

mechanism provided on the plane, and proper irons have

backsides that are

without any notches; i.e. they are featureless and flat.

The first and second model, pictured here, of the

plane are vary scarce and

collectible. These two models have a fancy, floral cast

lever cap, which sort

of resembles a shoe-buckle. A small lever cap wheel

(four-pronged and cast of

brass on the first model, knurled and cast of iron on the

later models)

activates the lever cap. The lever cap is held captive by

the rod, which screws

into the left check of the plane. Since the cap is so

delicate, it is often

found broken either where it pivots on the rod or back where

the tightening

wheel threads into it.

By the early 1880's, the plane took on a more

conventional appearance,

losing its Victorian look. Because the of the lever cap's

fragility it was no

longer held captive to the plane, and lost its intricate

design save for a six

or five pointed star cast into it until the early 1890's.

The lever cap from

then on was featureless, making a dull plane even duller.

Sometimes, the later

lever cap is so badly damaged that the tightening wheel can

no longer place

sufficient pressure on the iron to keep it set. Thus, it's

possible to find

these planes with crude repairs and ingenious means to hold

the iron in place,

with one of the most common being the removal of the lever

cap altogether in

favor of a simple wooden wedge that's driven under the cross

rod. Seems kinda

retro, recalling the days of old when wooden wedges held

irons in place, but it

actually works.

The front knob is often replaced on the earliest

models, since it is friction

fit inside a raised boss in the bottom casting. Many guys

solved the problem of

the knob falling out by drilling a hole through the main

casting and then

securing the knob with a screw. The first model of the plane

is the rarest of

all types, and has a distinct boat-shape to it. It's a nice

looking plane,

albeit very fragile - the aforementioned breakage to the

lever cap is most

common, followed by cracks in the cheeks and about the

mouth.

The problem of the front knob falling out of the

plane was solved by

screwing it directly onto a raised thread boss cast into the

main casting.

Planes with this feature have rosewood knobs until after

WWII, at which time

they became stained hardwood.

Because the plane has no adjustment features, other

than your setting the

iron by hand, the iron's backside is flat. Any holes or

grooves in the backside

mean it's a replacement. The iron can often be found

mushroomed at the top due

to its being set by a hammer in a manner like wooden planes

are set.

Be sure to check where the lever cap's tightening

screw threads into the

lever cap for any sign of crack in the tapped boss. Also,

check the lever cap

about the area where it rests under the rod (that spans the

side of the plane)

for any signs of cracks; on the later models this part of

the lever cap is

somewhat fragile due to the void cast in the lever cap.

#112 Scraper plane, 9"L, 3"W (2 7/8", 1925 on), 4lbs, 1885-1944.

In the humble (hah!)

opinion of the author, this is one of the finest tools ever

to have been

unleashed on the public from New Britain, Connecticut. For

the longest time,

the plane labored in relative obscurity among a cult of

those adroit in the

fine points of scraping. It used to be that these things sat

unloved at tool

events and auctions, and one almost ducked for cover when

asking $75 for one.

However, a popular scratch n' sniff magazine prominently

featured the plane on

the cover of an issue, and the prices of the things have

never been the same.

Everybody wants one, and once you use one, you'll see why.

Hey, my life isn't

complete without one, and I gotta have one - press here to order.

In the humble (hah!)

opinion of the author, this is one of the finest tools ever

to have been

unleashed on the public from New Britain, Connecticut. For

the longest time,

the plane labored in relative obscurity among a cult of

those adroit in the

fine points of scraping. It used to be that these things sat

unloved at tool

events and auctions, and one almost ducked for cover when

asking $75 for one.

However, a popular scratch n' sniff magazine prominently

featured the plane on

the cover of an issue, and the prices of the things have

never been the same.

Everybody wants one, and once you use one, you'll see why.

Hey, my life isn't

complete without one, and I gotta have one - press here to order.

The tool is nothing but the #12 configured like a #4 smoothing

plane. It has the typical rosewood knob and tote like

those found on the Bailey

bench planes, and it is gripped and pushed just like the

bench planes are.

Optional cutters could be purchased to turn the plane into

a toothing plane;

the toothing cutters were available in 22, 28, and 32

teeth per inch. These

same cutters also fit the #12.

The earliest model has a bead at the bottom of its

front knob. The blades on

these first models have the top edge beveled at both

corners, probably to spare

the workman's hand/knuckles/fingers should his grip ever

slip and slam into the

blade (this same blade can also be found on the earlier #12's). These

blades are not common at all, and they were probably soon

dropped in favor of

ones with a straight edge along both short dimensions

(across the width) of the

blade for the reason that some folks like to have both

ends of the blade with a

burr to be at the ready when one edge goes dull.

The earliest models do not have the number cast into

them. They also have

the patent date (8/31/58) stamped into the brass adjusting

nut closest to the

tote. The astute reader will note that the patent date on

the nut is nearly

some 30 years earlier than the supposed year this plane was

introduced. Since

the patents expired by the time this plane was offered in

the catalog, it seems

odd that Stanley would put this nut on the #112. Perhaps they were doing it to intimidate would

be copiers, ignorant

of patent law, as a warning, but it's more likely that

they were just using up

old stock since the same nut can be found on the #12's produced

during this time. It may be possible that Stanley produced

the plane prior to

1885, perhaps 10 years earlier (catalogs and production

dates were many times

out of synchronization) while the patent was still

applicable.

Look at the spewage for the #12 for things that can be damaged

on this plane. In

addition, check the area of casting, from the sole, where

the handle rests.

There is a rather fragile extension to the main casting

here, which sometimes

can be found broken. Never buy one with a high knob of the

style found on the

bench planes - they only came with the low knob (although

some models have a

taller than usual low knob that's unique to this plane).

Strangely, many of the earlier planes (say up to WWI)

have an unusually thin

coat of japanning, making it common for the planes to be

found with their finish

peeling or blistering. Maybe someone in the #112 department was taking home bottles of

japanning to paint the town

black?

#113 Circular plane, 10"L (10 1/4", 1936 on), 1 3/4"W, 3 1/2lbs, 1879-1942.

You would think that the

two other Stanley circular planes would have satisfied

Stanley, but no, they

had to come up with another design. This one probably arose

from the need to

compete with Leonard Bailey's better Victor design, the #20, where the

adjustment of the front and rear portion of the sole

occurred in unison via a

single adjusting knob.

You would think that the

two other Stanley circular planes would have satisfied

Stanley, but no, they

had to come up with another design. This one probably arose

from the need to

compete with Leonard Bailey's better Victor design, the #20, where the

adjustment of the front and rear portion of the sole

occurred in unison via a

single adjusting knob.

This plane has the typical thin steel sole attached

to the main casting by

dovetailed keys (the earliest design) or screws (later

design to solve the

problem of the sole breaking free). A large, mushroom-shaped

knob, located on

the front of the plane, adjusts the flexible sole by raising

a screw that is

attached to the forward pivoting arm. This arm is connected

to a gear, located

on the left of the main casting, which, in turn, drives

another gear that is

connected to the rear arm. Thus, both portions of the sole

are adjusted

simultanously. Later models have graduations machined into

the gears to help

set the plane to a particular curvature.

The earliest models of the plane have a japanned

lever cap with a fancy

nickel plated screw. The lever cap sits into two slots on

either side of it.

Depth adjustment of the cutter is done by a side wheel (on

the right) that

activates a clever sliding section that's machined into the

bed. The front knob

is also decoratively cast and nickel plated; it's embossed

"STANLEY RULE

AND LEVEL CO." in a circular fashion, with "PATENTED

SEPTEMBER 25,

1877" inside the previous embossing, followed by a Greek key

pattern

inside the patent date. Both the front and rear arms are

straight. There is no

lateral adjustment mechansim.

Later planes have the typical Bailey style

adjustments. The plane's main

casting was redesigned to accomodate the full features of

the bench plane

design - the brass depth adjustment screw, the lateral

adjustment lever, and

the slotted lever cap. The rear arm of the plane is curved,

whereas the front

arm is straight, just like the earlier models.

There is a scarce later variant of this plane, where

it has the full Bailey

patented features as well as a highly decorative nickel

plated front knob. This

knob has a four-lobed decoration cast into it, and was often

used on the planes

that Stanley made under contract for hardware firms such as

Keen Kutter.

Check the linkages on

the

sole for any signs of stress tears. Also check the area

where the sole is

dovetailed to the main casting for any cracks. Make sure the

grip for the rear

hand (behind the cutter) is present and secured tightly -

many of these planes

have had their grip screws stripped off or are missing the

grip altogether.

Check the linkages on

the

sole for any signs of stress tears. Also check the area

where the sole is

dovetailed to the main casting for any cracks. Make sure the

grip for the rear

hand (behind the cutter) is present and secured tightly -

many of these planes

have had their grip screws stripped off or are missing the

grip altogether.

Also check the slots in the main casting where the

old style lever cap

engages the main casting - this area is prone to chipping

and cracking. For

working purposes, make sure the sole adjusting screw isn't

stripped (adjust the

sole through its entire range) and that the cutter depth

adjustment wheel moves

the plate up and down freely (remove the iron to inspect

it). Check under the

front knob for any signs of repair to it, where it fits onto

the threaded rod

that raises/lowers the front arm. While inspecting this

area, check the main

casting itself, right behind the adjuster, since some of the

planes break here

and are welded back together.

Adjust the iron up and down with it in the plane. The

cap irons are unique

to this plane, and they can be found with cap irons taken

from a standard #3. The slot in

the cap iron is located higher up on the compass planes

than it is on the bench

planes. If a #3 cap iron is used on this

plane, it's impossible to

get a satisfactory set on the iron.

I don't really like this plane for the reason that

its sole can go out of

set during use. The same knob that's used to adjust the sole

is also used to

grip during planing. So, it's easy to change the adjustment

of the sole.

Stanley recognized this problem, and provided the later

planes with a set screw

that tightens the knob after the sole has been set. This

screw sits just

forward of the knob and is received by the main casting,

which is split so that

it can pinch the knob. The earliest models do not have this

screw. Despite my

dislike of the plane, others didn't - it's probably (in my

experience) the most

numerous of the four compass planes that Stanley sold, the #13, #20, #20 1/2, and #113.

#118 Block plane, 6"L, 1 5/8"W, 1 1/4lbs, 1933-1973.

I love this plane, not

because it's a good one to use, but because of its

description in the catalogs

- it was advertised as being "boy proof."

I love this plane, not

because it's a good one to use, but because of its

description in the catalogs

- it was advertised as being "boy proof."

The plane was designed for use in manual training and

rough work. It has a

pressed steel bottom, and has only three separate parts to

it - the cap, the

bottom, and the cutter. All screws are captive to the plane.

There are two circular cutouts, one on each side of

the plane, that are a

cheap substitute for the Hand-y grip, which is found on the

better block

planes.

The plane is finished with a thin black paint, which

often is found peeling.

The embossing at the toe, both "STANLEY" and "No. 118", of

the plane can sometimes be found with orange or red paint to

highlight it. The

exterior is machined, and the screws are nickel plated.

Later examples will

have the identifying marks stamped into the left side of the

plane. The later

models will also have a gray colored finished to the lever

cap.

The cutter is pitched at 12 degrees, and is

adjustable by an end screw.

There is no adjustable mouth on this plane. This plane is

also a piece of junk

when compared to the other low angle block planes, but some

might find it

useful to strip paint.

#120 Block plane, 7 1/2"L (7", 1917 on), 1 3/4"W (1 5/8", 1909 on), 1 3/8lbs, 1876-1950.

Like the #110, but with an

adjuster like that found on the #103. It's a piece of junk. Use it

as a clay pigeon, or

something like that, but only if it isn't the earliest

model, which is a very

scarce tool.

Like the #110, but with an

adjuster like that found on the #103. It's a piece of junk. Use it

as a clay pigeon, or

something like that, but only if it isn't the earliest

model, which is a very

scarce tool.

The first model, pictured here, is characterized by a

5-point star embossed

on the lever cap, and is one of Stanley's scarcest block

planes. It also has a

turned applewood knob that slips into a cast socket. The

next model used a

similar knob, but it's threaded onto a cast boss, and the

lever cap has the

common 6-point star. The later models have a smooth lever

cap, and are

interchangable with the cheezier #110. In what must have been an

attempt to make crap

shine, Stanley eventually provided a rosewood knob on this

thing and finally

settled upon a stained hardwood knob near the end of the

plane's life.

The adjustment mechanism on the first model is

identical to that used on the

Liberty Bell planes. The earliest #120

iron has a slot cut in it, much like that found on the

bench planes, through

which a slotted screw passes. The bottom of the screw

engages the adjustment

mechanism, whereas the top is fastened with a nut. As the

iron is used, the nut

and screw are moved 'up' the slot in order to take

advantage of the adjusters

range. The cutter has the patent date of "Pat. April 18.

1876"

stamped into it.

Soon after the debut of this plane, the adjustment

mechanism was changed

probably because it proved to be too complex for such a

cheap plane. The back

of the iron used on the later models has a series of grooves

milled in it to

engage a simpler adusting lever. This lever is pinned to two

raised bosses on

the main casting, and they should be checked for cracks, if

you're considering

buying this cheap tool.

#122 Smooth plane, 8"L, 1 3/4"W, 2 3/8lbs, 1877-1917.

This plane has the same

lever cap and adjusting mechanism as that found on the #104 and #105 (see the #135 for its larger brother

exposed). It is a wood

bottom version of this style of cheap plane. It has no

tote, but, instead, has

a raised portion of the casting to fit into the palm.

Sometimes, this portion

is broken, and the rest of the casting, which is screwed

to the wooden body,

can sometimes crack so you should examine it carefully.

This plane has the same

lever cap and adjusting mechanism as that found on the #104 and #105 (see the #135 for its larger brother

exposed). It is a wood

bottom version of this style of cheap plane. It has no

tote, but, instead, has

a raised portion of the casting to fit into the palm.

Sometimes, this portion

is broken, and the rest of the casting, which is screwed

to the wooden body,

can sometimes crack so you should examine it carefully.

The iron rests upon two vertical and triangular

(almost fin-like in

appearance) projections of the main casting. Between these

two projections is

housed the linkages that permit the iron to be adjusted. The

lowermost part of

the adjusting mechanism is grooved to receive the tab that's

secured to the cap

iron. Check this grooved portion of the adjusting mechanism

to make sure that

it isn't broken - it can sometimes be found snapped

rendering the adjuster

useless.

Since the plane is fairly short, and the casting

crowds the area where the

adjusting mechanism is, the two-pronged lever that's common

to the larger

planes of the series is replaced with a lever that has a

finger loop. The lever

is cast iron and it, too, can snap or crack, so check it out

before buying.

The sole and the knob are beech, as is all the wood

on the rest of this

series. Most of these planes, and their larger brothers, are

found in dogmeat

condition and have very little appeal to collectors/users,

but antique shops

don't realize this since most of them are priced way more

than they are worth

as firewood.

The lever caps for these wooden Liberty Bells are not

interchangable with

their two metallic brothers; the wooden models use longer

lever caps than the

metallic ones use. Also, you can't snarf parts from a Bailey

style bench plane,

be it wooden or metallic, as all the parts, save for the

iron, are unique to

this series of plane.

#127 Jack plane, 15"L, 2 1/8"W, 3 1/2lbs, 1877-1918.

Longer plane than the #122, but with a tote. It also has the pronged adjustment lever since there is room enough for it.

#129 Fore plane, 20"L, 2 3/8"W, 5 5/8lbs, 1877-1918.

Like the #127, only longer.

#130 Double end block plane, 8"L, 1 3/4"W (1 5/8", 1909 on), 1 5/8lbs, 1884-1955.

This is the cheaper model

of the two block planes that have two cutter seats, where

the cutter can be

turned end for end to make the plane either work regular or

bull nose. On the

regular end of the plane is a turned wooden knob (hardwood,

on earlier models,

and rosewood on the later models), which threads directly

upon a threaded boss

that arises from the main casting. Check that the knob

proper isn't stripped.

The plane does not have the common "Hand-y" feature found on

most of

Stanley's block planes.

This is the cheaper model

of the two block planes that have two cutter seats, where

the cutter can be

turned end for end to make the plane either work regular or

bull nose. On the

regular end of the plane is a turned wooden knob (hardwood,

on earlier models,

and rosewood on the later models), which threads directly

upon a threaded boss

that arises from the main casting. Check that the knob

proper isn't stripped.

The plane does not have the common "Hand-y" feature found on

most of

Stanley's block planes.

The first model of the plane has a star cast into the

lever cap, and the

side rails of its main casting are more arched over their

lengths. The casting

was soon redesigned so that each of the side rails have a

noticeable flat

length, with two curved portions meeting the flat length.

The proper irons on

these earlier models will have the plane's patent date

stamped in it -

"PAT'D JAN.30.82" with "REIS'D OCT.23.83" immediately

below. Later models of the plane have the typical logos that

are found on other

planes/tools. Since the plane hasn't any adjustment

mechanism, the backside of

the iron is flat; never buy one of these planes with a

grooves milled into it

backside, if you're collecting.

There are two rods that span the sides of the plane,

which engage the

typical lever cap with the large wheel underneath. The plane

looks like the #110, but with a bull

nose end to it. Adjustment of the cutter is done manually.

The cutter rests

upon two triangular and fin-like projections that rise

from the main casting.

At the 'apex' of these projections is a semicircular shape

where the iron makes

contact. Check that these projections aren't cracked. The

early planes will also

have the patent date cast (incised) between the two

projections; "PAT.

OCT. 23. 83" in fine, barely legible characters.

Check the casting on the bull nose end of the plane

for any cracks or signs

of repair. Some guys would roll their own #97 by grinding off the bull

nose end of the plane to

lay the cutter bare in order for it to function like a

chisel plane.

#131 Double end block plane, 8"L, 1 3/4"W (1 5/8", 1909 on), 1 1/2lbs, 1905-1941. *

This is the same basic

plane as the #130,

except that it has the depth adjustment mechanism and same

style of lever cap

as found on the #60 series of block planes. It

also has the Hand-Y

feature, two on each side, milled for gripping; four

Hand-Y grips are obviously

better than just two. This is a fairly tough plane to

find, especially free of

damage.

This is the same basic

plane as the #130,

except that it has the depth adjustment mechanism and same

style of lever cap

as found on the #60 series of block planes. It

also has the Hand-Y

feature, two on each side, milled for gripping; four

Hand-Y grips are obviously

better than just two. This is a fairly tough plane to

find, especially free of

damage.

A clever modification to the depth adjusting screw is

the cool idea behind

this tool. Imagine your basic depth adjusting screw, like

that on the #118 (it's a few planes

before this one's description), that can pivot down at its

bottom so that the

adjusting knob can be flipped from end-to-end relative to

the plane's sole. If

you can think of that, then you can see how that sort of

adjuster can benefit

this plane since it has two mouths. However, for this

adjustment to be

beneficial, it needs to engage the back of the cutter when

the cutter is in

either position. Thus, the sliding portion of the adjuster

has two machined

faces on it, both of which have a small nib to engage the

cutter, and its these

faces that slip into their corresponding pair of inclined

bosses that arise

from the main casting. A perfect solution for two-position

adjustability, or so

one would think, but there are problems with it.

The sliding portion of the adjuster is cast from

iron, and is rather thin

where it mates with the inclined bosses. It also can spin

about the adjusting

screw when it's not seated. The problem here, then, is that

the sliding portion

can be cocked just enough so that when you flip the

adjuster, the edge of the

sliding portion slams into the non-machined area of the

bosses causing the

sliding portion to crack and chip. This is a very common

form a damage found on

these planes.

Furthermore, because

the

bottom of the adjuster is a fulcrum point, the main casting

can crack or chip

where the adjuster pivots. The adjusting yoke (which itself

is secured to the

main casting with two screw, each driven from the side of

the plane) also can

crack about its pivotting point. This area of the plane

needs very close

inspection.

Furthermore, because

the

bottom of the adjuster is a fulcrum point, the main casting

can crack or chip

where the adjuster pivots. The adjusting yoke (which itself

is secured to the

main casting with two screw, each driven from the side of

the plane) also can

crack about its pivotting point. This area of the plane

needs very close

inspection.

The plane does not have a lateral adjustment lever;

the would have been an

impossibility for Stanley to pull-off without making the

plane too complex. The

lever cap screw (the one that engages the lever cap to act

as a fulcrum point)

is repositioned in the main casting to the respective mouth

position; i.e.

there is only one lever cap screw on the plane. Were there

two lever cap

screws, the adjuster couldn't slide over a suitable range.

The plane has a rosewood knob that threads directly

onto the main casting.

The plane is japanned with its exterior machined. The

adjuster, the sliding

section, and the yoke are all nickel plated. The plane is

embossed with its

model number behind the knob. The first model of the plane

has the patent dates

embossed on the main casting (note that it also has a wider

cutter). If you

need a cutter for the plane, any common 1 5/8" wide block

plane cutter,

with machined grooves in the back, will work. As with the #130, check the casting about

the bull nose mouth for

any signs of cracks or repairs.

#132 Jointer plane, 26"L, 2 5/8"W, 7 3/8lbs, 1877-1918.

Like the #129, only longer.

#135 Smooth plane, 10"L, 2 1/8"W, 3lbs, 1877-1918.

|

|

|

Like the #122,

but with a tote and a two-pronged lever. The rear portion

of the plane is

stepped in a razee-fashion, like the #35 is designed.

If you look closely at the iron in the rightmost

image, you'll notice a slot

in the cap iron, below the cap iron's screw. In this slot is

a little steel

piece that engages the groove in the adjusting mechanism to

raise and lower the

iron. This little piece has a tongue milled on it and is

held to the cap iron

with a six-sided nut that's mounted on the opposite side of

the cap iron.

Note that the casting that carries the adjusting

mechanism is different than

that used on the #35; this casting is shorter

in length and doesn't

follow the razee (curved rearward area of the stock)

section to carry the tote.

Instead, the tote is simply screwed to the beech stock and

has an additional

screw at the toe of the tote.

#140 Rabbet and block plane, 7"L, 1 3/4"W (1 5/8", 1936 on), 1 1/8lbs, 1896-1944.

This is a very useful

plane, and is one of Stanley's better products (it would

have been even better

if they didn't supply it with the cheesy lever cap wheel

like that found on the

#110, et al, and

if it had an adjustable mouth). The plane can be used to

trim crossgrain

rabbets, the cheeks of tenons, for cutting rabbets,

general block plane work,

etc. The plane's number is embossed on its heel.

This is a very useful

plane, and is one of Stanley's better products (it would

have been even better

if they didn't supply it with the cheesy lever cap wheel

like that found on the

#110, et al, and

if it had an adjustable mouth). The plane can be used to

trim crossgrain

rabbets, the cheeks of tenons, for cutting rabbets,

general block plane work,

etc. The plane's number is embossed on its heel.

The right side of the plane has a removable plate,

and is secured in place

by two slotted screws. With the plate on, the plane

functions as a regular

block plane. With the plate off, the plane becomes a rabbet

plane (the cutter's

right edge coincides with the rightmost edge of the sole).

The earlier side

plates have the patent date stamped into them. You can

sometimes find a huge

burr on either the front and/or rear edge of the side plate.

This burr results

from grinding the side plate attached to the main casting

during manufacturing.

You may want to file the thing off (but only if the plane is

a user and not a

collector) since you can draw blood from it if you're not

careful.

Also on the right side of the plane, on its

sole (this would be the

left side of the plane when you flip it over and look at

it), can often be

found a

high or low spot at the back of the mouth. This area results

from movement in

the main casting after it was machined, where the sole

can twist over its

length. The only portion of the plane that can possibly lend

assistance in

keeping the sole flat, the right cheek of the casting, isn't

sufficient to keep

the sole ahead of the iron and sole behind the iron

co-planar. The twisting

resulted either from a casting that wasn't allowed to season

sufficiently prior

to machining or from just sloppy machining by a New Britain

Joe Timeclock what

was nursing a hangover or something. When you note this

'problem', it's

certainly one plane that can benefit from the lapping craze

that has the free

planing world firmly in its grip.

A flat lever adjustment mechanism, like that provided

on the cheap #120 plane, is found on

the first model of these planes, but it was soon replaced

with the depth

adjusting screw that's found on the #60 series of block planes. The

lever adjuster just

doesn't hold the cutter firmly in place like the knob

adjuster does. The cutter

is pitched at 20 degrees with its cutting edge ground to a

slight skew, which

makes it cut across the grain better. The cutters used on

both models of the

tool have a series of fine grooves pressed into the

backside of the iron. These

grooves engage a corresponding piece of the adjuster to

grip the cutter firmly.

Like any of the block

planes with the depth adjustment screw, be sure to check

that the threads of

the screw are not stripped. If the plane has a cast

adjustment knob, like the

one to the right in the photograph, check that it hasn't

been snapped off and

then brazed back onto the threaded rod.

Like any of the block

planes with the depth adjustment screw, be sure to check

that the threads of

the screw are not stripped. If the plane has a cast

adjustment knob, like the

one to the right in the photograph, check that it hasn't

been snapped off and

then brazed back onto the threaded rod.

Give the plane a good inspection on its left side in

case there are any

cracks or repairs. When the side plate is off the plane, the

left side of the

plane, just to the left of the mouth, is the only area that

is keeping the

plane's main casting in one piece.

The plane is often found missing its side plate -

these plates all reside in

the same realm as lost slitting cutters, cam rests, fences

for #289, etc. If

the side plate is present, don't jump for joy until after

you've checked the

screws that secure it to the plane. One or both of these

screws are often

missing or replaced. Missing screws should be rather

obvious to notice, but

replaced ones aren't. Original screws have a flat head,

often with vertical (in

relation to the shaft) knurling. They aren't brass, as

many replacement ones

are. The lever cap screw is also often replaced, for some

strange reason. This

screw is unique among the block planes, but you can snarf

a replacement from a

common #78.

A small, rosewood knob is threaded directly onto the

main casting to act as

a finger rest. This knob is often split or stripped. If so,

the same rosewood

knob from the common block planes, like the #110 or #120, can be used as a replacement.

The lever cap, fully nickel plated, is unique to this

plane, so be cautious

of replacements. A proper lever cap has a noticeable arch on

its right side, so

that it functions as part of the plane's side when the side

plate is removed.

The cutter is also unique to the plane; it has parallel

sides, which become

narrower about 1/3 back from the cutting edge, with the heel

of the iron

rounded. Make sure that a common block plane iron has not

been substituted in

the plane.

[ START ] |

[ PREV ] | [ NEXT

] | [ END ]

[ HOME

]

Copyright

(c) 1998-2012 by Patrick A. Leach. All Rights Reserved.

No part may be

reproduced by any means without the express written

permission of the author.